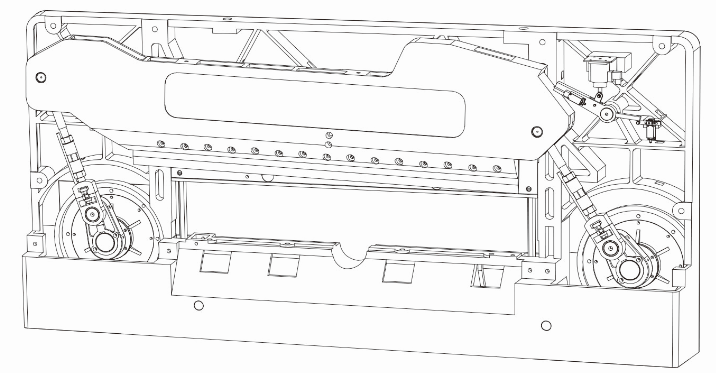

1. Double worm wheel paper cutting machine: This series of double worm wheel and double guide rail slotless workbench paper cutting machines The high-speed ball screw, linear guide rail, and slotless workbench form a box type paper feeding mechanism to ensure accurate positioning of the paper feeder under high-speed movement. The paper pressing mechanism is driven by hydraulic pressure and the pressure is stepless and adjustable, The pressure adjustment range is large. The cutting mechanism is driven by a worm screw through an electromagnetic friction clutch to drive a double worm wheel while dragging the cutting bed. The pulling rod of the cutting bed is equipped with an overload safety device, an infrared photoelectric device, an electronic knife lock device, and a synchronous button operation device for both cutting hands. Therefore, this series of machines has the characteristics of particularly high cutting force, high cutting accuracy, convenient, safe, reliable operation, and durability, especially suitable for cutting various hard materials such as honeycomb paper, adhesive cardboard, PC board, etc.

2.

Double guide rail paper feeding system: The paper pushing system adopts imported Chinese * * linear guide rails and ball screw, which is wear-resistant and has strong impact resistance.

3. 19 inch TFT true color LCD screen: This series of programmable computer displays adopts a 19 inch true color LCD screen, and the main chip of the computer adopts American industrial grade chips. The multilingual operation interface is equipped with a handwheel encoder, making user operation more user-friendly. It can achieve self fault diagnosis function and animated operation mode display. The programming capacity reaches 200 groups, with each program group having 200 different positions for cutting data. The data is stored in memory for over 300000 hours, ensuring the reliability and stability of performance. The paper feeding motor adopts a servo motor, with a paper feeding speed of 16-28 meters per minute and a paper feeding positioning accuracy of 0.01 millimeters

4. Safety protection system: The machine adopts safety devices such as light controlled safety devices, synchronous button operation for cutting action with both hands, and electronic knife lock single cycle cutting to protect operators from safe operation

5. Overload protection device and safe and fast tool changing method

6. Blade ejection device

7. Workbench chrome treatment: The surfaces of the workbench and side panels are treated with chrome to enhance surface smoothness and accuracy.

8. Work Platform Gas Beads: The entire work platform is evenly distributed with gas beads, making paper feeding work more convenient and easy.

9. Special electronic knife lock: providing safety factor and improving production efficiency

10. Heavy duty resin sand body, without warping.

11. Optical knife line lamp device, providing production efficiency.

12. Quality Standard: The quality of this series of paper cutting machines meets the Chinese People's * * * Machinery Industry Standard JB/T 8115-2010

13. Safety standards: Comply with European CE standards.

Model | SQZK1850D-19 |

Max cutting width | 185 |

Max cutting length | 195 |

Max cutting height | 16.5 |

Main motor power | 7.5 |

Cutting speed | 45 |

Weight | 8500 |

Width of machine with sideway | 394 |

Width of machine without sideway | 375 |

length | 350 |

height | 177 |

Smallest cut without false clamp | 3.5 |

Smallest cut with false clamp | 11 |

Knife thickness | 203x16x1.37 |

Packing size (LxWxH) | 403x206x240 |